For Contractors, Dealers, and Builders

In the competitive landscape of residential construction and high-stakes remodeling, the visual language of the kitchen often dominates the initial dialogue between contractor and client. The selection of door styles—whether the clean lines of a shaker profile or the intricate detailing of a raised panel—and the choice of finish typically consume the majority of the design phase. However, for the seasoned contractor, the dealer focused on long-term reputation, and the builder minimizing liability, the true measure of a kitchen’s quality lies not in its static appearance, but in its kinetic performance.

The “feel” of a kitchen—the tactile experience of opening a pantry, the silent deceleration of a drawer, and the weightless lift of an overhead cabinet—is defined entirely by the mechanical hardware hidden behind the façade. A door that sags, a lift that drifts, or a drawer that slams effectively communicates “cheapness,” regardless of how expensive the quartz countertop or the appliances were. Conversely, a door that glides effortlessly, closes silently, and stays perfectly aligned for years communicates “craftsmanship.”

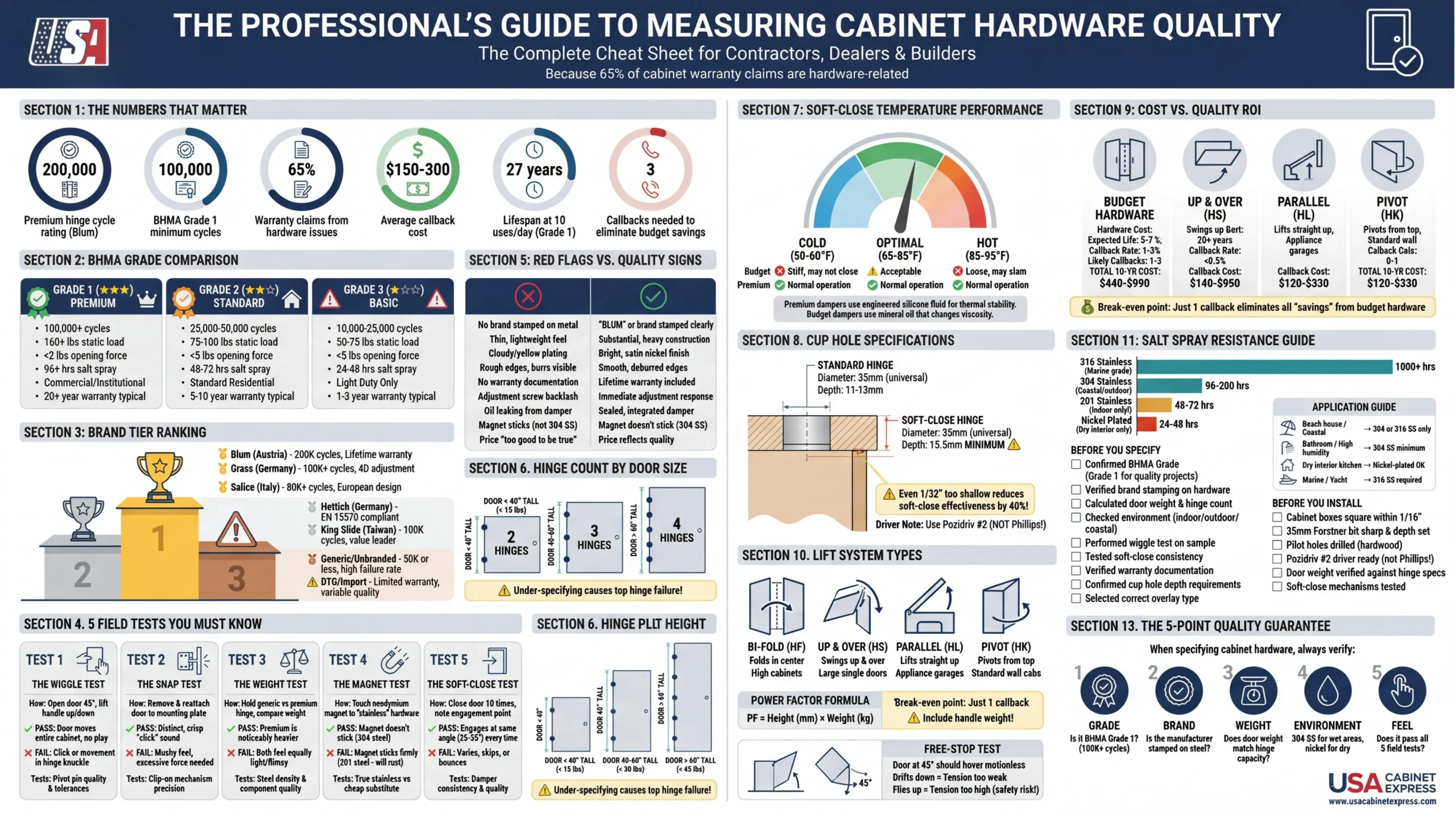

The difference between premium and economy cabinet hardware often comes down to one number: 200,000 versus 50,000 cycles. This cycle count—representing how many times a door can open and close before failure—is just one of dozens of metrics professionals must evaluate. Hardware issues account for approximately 65% of all cabinet warranty claims, making mechanism selection one of the most consequential decisions in any cabinet project.

This comprehensive guide provides an exhaustive technical analysis of kitchen cabinet door opening mechanisms, moving beyond superficial metrics of price and aesthetics to explore the metallurgy, engineering physics, and rigorous testing standards that separate professional-grade hardware from commodity alternatives.

At-a-Glance: Professional Hardware Selection

| Metric | Budget Grade | Mid-Range | Premium Grade |

|---|---|---|---|

| Cycle Rating | 25,000–50,000 | 50,000–80,000 | 100,000–200,000 |

| BHMA Grade | Grade 3 | Grade 2 | Grade 1 |

| Steel Gauge | <1.0mm | 1.0mm | 1.0–1.2mm |

| Salt Spray Resistance | 24–48 hrs | 48–72 hrs | 96–100+ hrs |

| Static Load (Hinges) | 75 lbs | 100 lbs | 160+ lbs |

| Warranty | 1–3 years | 5–10 years | Lifetime (20+ yrs) |

| Price per Kitchen (20 doors) | $140–$300 | $280–$500 | $440–$900 |

| Callback Rate | 1–3% | 0.5–1% | <0.5% |

Essential Benchmarks: • Key certifications: BHMA Grade 1, KCMA A161.1, EN 15570 Level 3

• ROI threshold: 3 callbacks eliminate budget savings

• Top brands: Blum, Grass, Salice, Hettich (premium) | King Slide (value)

• Critical spec: Cup hole depth 11-13mm (standard) | 15.5mm (soft-close)

• Steel standard: 304 stainless for outdoor/coastal; nickel-plated for indoor

The Strategic Importance of Kinetic Hardware

The Hardware as the “Engine” of the Cabinet

It is a common metaphor in the industry to view the cabinet box as the chassis and the hardware as the engine. A luxury car with a failing transmission provides a poor user experience regardless of the quality of its leather seats; similarly, a kitchen with custom maple doors that sag, bind, or slam is perceived as “cheap” by the homeowner, regardless of the material cost.

The opening mechanism is: • The primary user interface of the cabinetry

• The component subjected to the most physical stress

• The highest frequency of interaction

• The greatest variability in load

• The highest risk factor for system failure

While a plywood box is static and stable, a hinge is a dynamic machine involving friction, torque, and fatigue. Industry data suggests that a significant percentage of post-installation callbacks are related to door alignment and operation rather than finish defects.

The Economic Impact of Failure: Callback Cost Analysis

To understand the value of quality measurement, one must first quantify the cost of failure.

The Economics of a Single Hinge Failure:

| Cost Category | Typical Range | Notes |

|---|---|---|

| Truck Roll (Minimum) | $150–$300 | Travel time, fuel, dispatch overhead |

| Technician Labor | $100+/hour | Skilled finish carpentry rates |

| Opportunity Cost | Variable | Time not spent on billable new projects |

| Reputation Cost | Significant | Single negative review can deter future leads |

The Math: Investing an extra $60-90 in hardware for an entire kitchen can insulate a contractor from thousands of dollars in potential liability. A single callback ($150-300) eliminates all “savings” from budget hardware.

The Resale Value Proposition

Beyond risk mitigation, high-quality opening mechanisms offer tangible value during property resale:

• Real estate professionals cite “soft-close cabinetry” as a key selling point

• Brand-name hardware (Blum, Hettich, Salice) communicates “luxury”

• Tactile resistance and smooth glide are sensory cues buyers associate with high-end construction

• Potential resale premium of 3-5% in competitive markets for quality-equipped kitchens

The Engineering of the Concealed Hinge

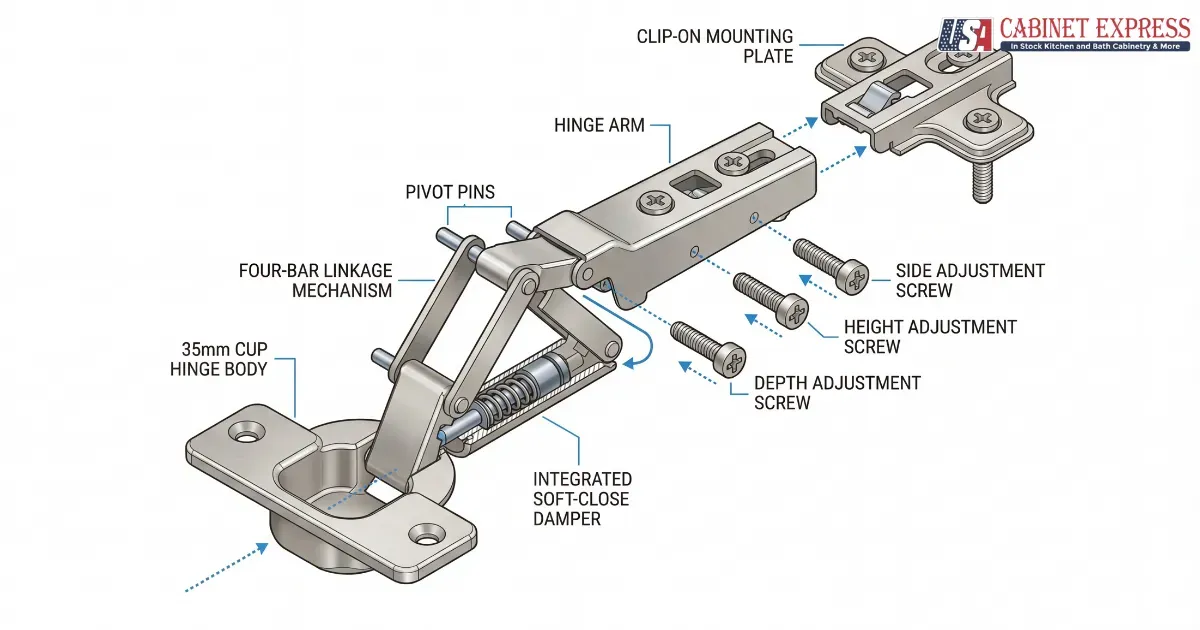

The Mechanics of the Four-Bar Linkage

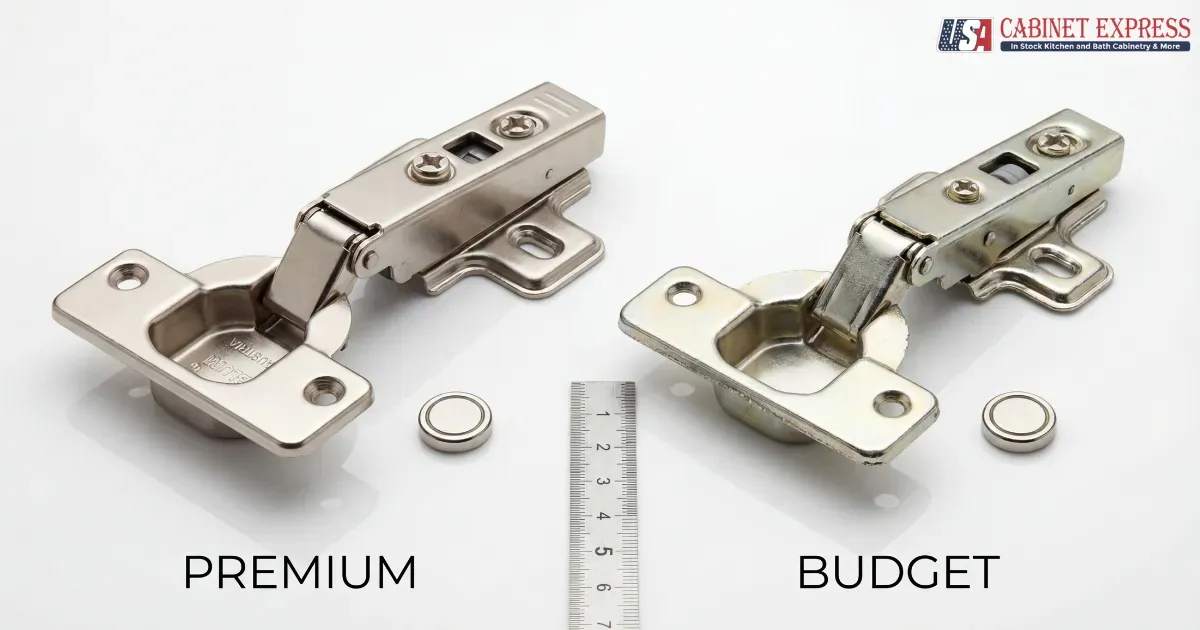

The modern European-style concealed hinge is a marvel of mechanical linkage design. Unlike simple barrel hinges of the past, which offered a single axis of rotation, the concealed hinge utilizes a four-bar linkage system (multi-pivot geometry) to throw the door out and away from the cabinet box before swinging it open.

Why This Matters: This complex motion path allows for tight reveals—the gaps between doors—without the door edge binding against the adjacent panel or the face frame.

Quality Indicators in Linkage Design:

| Component | Premium Specification | Budget Specification | Consequence of Poor Quality |

|---|---|---|---|

| Linkage Arm Steel | Cold-rolled, 1.0–1.2mm gauge | Thin stamped, <1.0mm | Door sag, flex under load |

| Pivot Pins | Hardened steel, lubricated / bushings | Soft steel, no treatment | Wear, “slop” in movement |

| Manufacturing Tolerances | Strict (±0.1mm) | Loose (±0.5mm+) | Misalignment, binding |

| Finish Quality | Bright, uniform nickel | Cloudy, yellowish | Higher corrosion risk |

The Flex Problem:

Thinner steel gauges (<1.0mm), common in generic imports, are prone to flexing under load. This flex manifests as “door sag” over time, where the weight of the door causes the hinge geometry to deform, resulting in misalignment that adjustment screws can no longer correct.

Face Frame vs. Frameless Cabinet Challenges

The American market is unique in its widespread use of face frame cabinetry, whereas the rest of the world predominantly uses frameless (Euro-style) construction. This distinction significantly impacts hinge selection and quality measurement.

Face Frame Compact Hinges:

Compact hinges mount to the edge of the face frame. Because they attach to a smaller surface area, the quality of the mounting plate and screw retention becomes paramount.

| Feature | Premium Compact Hinge | Generic Compact Hinge |

|---|---|---|

| Adjustment Axes | 6-way (3D) adjustment | 2-way or fixed |

| Depth Adjustment | Spiral cam screw | Loosen-and-slide slot |

| Overlay Accuracy | ±1/32″ precision | ±1/8″ or worse |

| Mounting Security | Steel cam plate | Plastic or thin metal |

The Spiral Cam Advantage:

The presence of a spiral cam screw for depth adjustment—rather than a loosen-and-slide slot—is a hallmark of professional-grade hardware. It allows for precise setting of the door gap without the risk of the door slipping out of position over time due to gravity or vibration.

Frameless (Euro) Hinges:

These hinges mount to the side wall of the cabinet using the “System 32″ mounting standard for interchangeable precision.

The Clip-On Advantage:

| Feature | Premium Clip-On | Budget Slide-On / Screw-On |

|---|---|---|

| Installation | Snap onto plate, no tools | Screws required |

| Door Removal | Instant, settings retained | Must re-adjust every time |

| Labor Savings | Significant | None |

| Adjustment Retention | Permanent | Lost with removal |

Premium hinges allow doors to be snapped onto the mounting plate without tools, using a robust spring-loaded latch. This allows doors to be removed for safe transport and painting, then reinstalled instantly without losing adjustment settings. Cheaper slide-on or screw-on hinges require re-adjustment every time the door is removed, adding significant labor costs.

Field Evaluation Tests for Hinges

For contractors receiving a shipment of cabinets, these quick quality control (QC) checks are vital:

TEST 1: The “Wiggle Test” (Pivot Pin Quality)

Procedure:

- Open the cabinet door to approximately 45 degrees

- Grasp the door handle firmly

- Gently lift up and down while holding the handle

Results:

| Result | Interpretation | Action |

|---|---|---|

| ✅ PASS | Door moves the entire cabinet box; no play in hinge joints | Accept hardware |

| ❌ FAIL | You feel a “click” or movement in the hinge knuckle before the cabinet moves | Reject — loose tolerances in pivot pins will cause sagging within months |

The “Snap Test” (Clip-On Quality)

Procedure:

- Remove the door from the mounting plate

- Reattach by pressing the hinge onto the plate

Results:

| Result | Interpretation | Action |

|---|---|---|

| ✅ PASS | Hinge engages with a distinct, sharp audible “click” and feels solid immediately | Accept hardware |

| ❌ FAIL | Engagement feels mushy, or requires excessive force to seat | Reject — poor machining of latch mechanism |

TEST 3: The Weight Comparison Test

Procedure:

Physically hold a generic hinge in one hand and a premium hinge (Blum, Grass, Salice) in the other.

Result:

The premium hinge will almost always be noticeably heavier. This weight correlates to: • Density and thickness of the steel

• Robustness of internal springs and dampers

• Overall material quality

Adjustment Screw Response

Procedure:

- Turn the adjustment screws slowly

- Observe door movement

Results:

| Result | Interpretation | Action |

|---|---|---|

| ✅ PASS | Door moves immediately and precisely with screw turn | Accept hardware |

| ❌ FAIL | Turn screw 2–3 times before door reacts (backlash), or screw strips under pressure | Reject — poor threading tolerances |

The Science of Soft-Close Technology

Fluid Dynamics in Micro-Cylinders

The integration of soft-closing damping systems has revolutionized user expectations for cabinetry. Originally an add-on device clipped onto the hinge cup or arm, modern premium hinges feature integrated damping mechanisms housed directly within the hinge cup or arm assembly. This integration protects the hydraulic cylinder from dust, grease, and impact damage.

The Physics of Soft-Close:

DOOR CLOSES → Hinge arm compresses piston →

Piston moves through silicone fluid → Fluid provides resistance →

Kinetic energy converts to heat → Heat dissipates harmlessly

The Quality Differentiator: Silicone Fluid

The quality of the silicone fluid is the “secret sauce” of premium manufacturers. It must maintain its viscosity characteristics across a wide range of temperatures.

| Fluid Type | Temperature Stability | Used By | Performance |

|---|---|---|---|

| Engineered Silicone | Excellent (50–95°F) | Blum, Grass, Salice | Consistent year-round |

| Mineral Oil | Poor (stiff cold, loose hot) | Generic imports | Seasonal problems |

Measuring Soft-Close Damping Quality

METRIC 1: Engagement Consistency (The “Catch Point”)

Test Procedure:

- Open the door fully

- Push it closed gently

- Note the angle where the damper takes over

- Repeat 10 times

Results:

| Result | Interpretation |

|---|---|

| ✅ PASS | Door engages at the exact same point (e.g., 30°) every time |

| ❌ FAIL | Engagement point varies, or door “skips” the damper if pushed too hard |

Note: Premium hinges typically engage between 25 and 35 degrees of closure. Inconsistent engagement suggests poor tolerances in the internal cam geometry.

METRIC 2: Temperature Stability

Kitchens experience significant temperature fluctuations, from cold winter mornings to heat during cooking sessions.

The Problem with Inferior Dampers:

| Temperature | Budget Damper Behavior | Premium Damper Behavior |

|---|---|---|

| Cold (50–60°F) | Stiff — may refuse to close completely | Normal operation |

| Hot (85–95°F) | Loose — door may slam | Normal operation |

| Optimal (65–85°F) | Acceptable | Normal operation |

Premium Solution: High-quality dampers use engineered silicone fluids that are thermally stable. A Blum hinge functions effectively identical at 60°F and 90°F.

METRIC 3: Adaptive Resistance Test

The Mechanism:

Advanced systems (like Blum BLUMOTION) have damper valves that adjust based on the speed of fluid flow: • If user slams the door → resistance increases to prevent impact

• If door is pushed gently → resistance decreases to ensure complete closure

Test Procedure:

- Slam the door hard

- Then push it just barely past the engagement point

Results:

| Result | Interpretation |

|---|---|

| ✅ PASS | System handles both extremes gracefully |

| ❌ FAIL | Door bounces open when slammed OR stalls out when pushed gently |

The Deactivation Feature

An often-overlooked feature of high-quality soft-close hinges is the ability to deactivate the soft-close function.

Why This Matters:

On very small or light doors, the resistance of two soft-close hinges might be too great, preventing the door from closing under its own momentum.

| Feature | Premium Hinges | Generic Hinges |

|---|---|---|

| Deactivation Switch | Yes — on cup or arm | Rarely available |

| Tuning Capability | Can disable one hinge of two | All or nothing |

| Result | Perfect closing speed regardless of door weight | Light doors may hang open |

This “tuning” capability is the mark of a master installer.

Vertical Lift Systems—Defying Gravity

The Ergonomic Shift

As kitchen design moves toward horizontal lines and wider wall cabinets, traditional side-hinged doors become ergonomic liabilities: • Wide doors swing far into the kitchen

• Obstruct traffic patterns

• Create head-impact hazards

Lift systems solve this by moving the door upward, out of the user’s workspace. However, evaluating lift system quality is more complex than hinges because it involves active weight management against gravity.

Lift System Types and Kinematics

| Lift Type | Motion Path | Best Application | Quality Indicator |

|---|---|---|---|

| Bi-Fold (AVENTOS HF) | Door splits / folds in center | High wall cabinets, easy handle reach | Safety stop in center hinge; smooth fold without binding |

| Up & Over (AVENTOS HS) | Single panel swings up & over | Large single doors, crown molding clearance | Lateral stability bar; door should not twist if lifted from one corner |

| Parallel Lift (AVENTOS HL) | Door lifts vertically, parallel to cabinet | Appliance garages, hiding microwaves | Smooth rail movement; no shuddering or racking |

| Pivot Lift (AVENTOS HK) | Door pivots up from top | Standard wall cabinets, heavy fronts | “Free-Stop” capability; precise tension balance |

The Power Factor Formula

The core metric for lift systems is the Power Factor (PF):

Power Factor = Cabinet Height (mm) × Front Weight (kg)

⚠️ Important: Include the weight of the handle in your calculation!

Manufacturers produce lift mechanisms in different strength ranges. The quality of a system is defined by how precisely it can be tuned to the specific Power Factor of the door.

The “Sweet Spot” Test (Free-Stop Evaluation)

Test Procedure:

- Open the door to a 45-degree angle

- Let go completely

Results:

| Result | Interpretation | Action Required |

|---|---|---|

| ✅ PASS (Free-Stop) | Door hovers motionless | Perfect balance achieved |

| ❌ FAIL (Drift Down) | Door slowly closes | Spring tension too weak OR mechanism undersized |

| ❌ FAIL (Fly Up) | Door springs upward | Tension too high — safety risk to user’s chin |

Premium Systems: Allow for precise, stepless adjustment of tension using a cordless drill, with a visual gauge to ensure both sides are balanced.

Generic Systems: Often have stepped adjustments (notch system) that may not allow for perfect balance, leaving the door always slightly fighting the user.

Gas Struts vs. Mechanical Spring Packs

| Feature | Gas Struts (Pneumatic) | Mechanical Spring Packs |

|---|---|---|

| Technology | Compressed gas and oil | Calibrated metal springs |

| Used In | Automotive, lower-cost cabinetry | Premium systems (AVENTOS) |

| Lifespan | 3–5 years typical | Decades |

| Temperature Sensitivity | High — pressure drops in cold | None |

| Failure Mode | Seals dry out, gas leaks | Minimal degradation |

| Failure Signs | Oil “weeping” around piston rod | Rare — may lose slight tension |

| Replacement Need | Every 3–5 years | Rarely, if ever |

| Warranty Recommendation | Problematic for builders | Safe choice for warranty coverage |

For builders offering a warranty, the mechanical spring is the only responsible choice.

Push-to-Open and Mechanical Latches

The Minimalist Imperative

As kitchen trends move toward handleless designs (“minimalism”), push-to-open mechanisms (like Blum’s TIP-ON) have gained prominence. These systems allow users to open cabinets with a knee or elbow bump—a significant functional advantage when hands are dirty or full.

Push-to-Open Quality Metrics

Trigger Sensitivity

| Sensitivity Level | User Experience | Quality Assessment |

|---|---|---|

| Too High | Cabinet feels stubborn | Poor design |

| Too Low | Accidental brushes pop drawers open | Poor design |

| Optimal | Deliberate but light touch required | Quality mechanism |

The “Bounce” Problem

Inferior latches often fail to catch the door if pushed too hard or too soft—the door “bounces” back open, frustrating the user.

Premium Solution (TIP-ON BLUMOTION):

Combines push-to-open trigger with soft-close damper:

- Door is pushed open

- When thrown shut, soft-close catches it

- Slows it down

- Latch engages silently

This engineering eliminates the “bounce” problem entirely.

Seismic and Vibration Considerations

In regions prone to earthquakes or heavy vibrations (near train lines), purely mechanical push latches can be problematic.

The Risk:

Strong vibration can trigger the spring mechanism, causing all cabinet doors to pop open simultaneously—potentially dangerous if contents fall out.

Quality Measure:

Premium latches include: • “Lockout” feature

• Required depth of compression (e.g., 2mm negative travel) to activate

• This prevents vibration-induced opening

The “Bump Test”:

Strike the cabinet frame with a rubber mallet. A quality latch should NOT disengage.

Material Science—Metallurgy and Corrosion

The Stainless Steel Grade Debate: 201 vs. 304

Not all “stainless steel” is created equal. The market is flooded with hinges made from 201 series steel, which has lower nickel content and higher manganese compared to industry-standard 304 series.

| Property | 304 Series (Premium) | 201 Series (Budget) |

|---|---|---|

| Chromium Content | 18% | 16–18% |

| Nickel Content | 8% | 3.5–5.5% |

| Corrosion Resistance | Excellent | Moderate — will rust eventually |

| Magnetic Response | Non-magnetic (or very weak) | Magnetic |

| Cost | Higher | Lower |

| Recommended Use | Outdoor, coastal, humid environments | Dry, indoor use only |

The Magnet Test

Contractors should carry a small neodymium magnet to test hardware on site.

Test Procedure:

Hold the magnet against the hinge steel.

| Result | Steel Grade | Recommendation |

|---|---|---|

| Magnet does NOT stick | Likely 304 stainless | ✅ Safe for outdoor / coastal use |

| Magnet sticks firmly | 201 or 400 series | ⚠️ Indoor use ONLY |

Critical Application:

For outdoor kitchens, beach houses, or high-humidity environments (bathrooms), only specify 304 stainless steel hardware.

Salt Spray Testing (ASTM B117)

Corrosion resistance is empirically measured using a salt fog chamber test, where hardware is exposed to a continuous saline mist.

| Performance Level | Hours to Red Rust | Application | BHMA Grade |

|---|---|---|---|

| Standard | 24–48 hours | Dry, climate-controlled kitchen | Grade 2–3 |

| Premium | 96–100+ hours | Humid, coastal, outdoor | Grade 1 |

Implication:

For coastal projects or outdoor kitchens, contractors must specify hardware with 100+ hour ratings. A standard 24-hour rated hinge will show pitting and rust within months in a beach house environment.

Industry Standards and Certification

ANSI/BHMA A156.9—The Bible of Cabinet Hardware

This standard dictates performance requirements and categorizes hardware into Grades (1, 2, 3), with Grade 1 being the highest.

Key Grade 1 Requirements for Hinges:

| Test | Requirement | Real-World Meaning |

|---|---|---|

| Cycle Test | 100,000 open / close cycles | ~27 years at 10 uses per day |

| Static Load Test | 160 lbs hung from open door edge | Survives child hanging on door |

| Permanent Set Test | Minimal sag after loading | Reveal lines stay crisp for decades |

| Operational Force | < 2 lbs to open | ADA-compliant, elderly-friendly |

Note: Some European standards and premium manufacturers test beyond ANSI baseline—up to 200,000 or even 1,000,000 cycles for heavy-duty commercial applications.

KCMA A161.1—The System Standard

While BHMA tests individual hardware, KCMA A161.1 tests the cabinet system as a whole, including attachment of hardware to the wood.

KCMA Chemical Finish Tests

Hardware is subjected to exposure to common kitchen substances for 24 hours:

| Substance | Test Duration | Passing Criteria |

|---|---|---|

| Vinegar | 24 hours | No discoloration |

| Lemon juice | 24 hours | No blistering |

| Orange juice | 24 hours | No rusting |

| Grape juice | 24 hours | No finish damage |

| Ketchup | 24 hours | No staining |

| Coffee | 24 hours | No etching |

| Mustard | 24 hours | No discoloration |

This is vital for kitchen environments where acidic spills are inevitable.

Comprehensive Standards Comparison Table

| Test Type | Metric | Standard Grade (2/3) | Premium Grade (1) | Real-World Implication |

|---|---|---|---|---|

| Cycle Life | Open / Close Repetitions | 25,000–50,000 | 100,000+ | Longevity (≈25+ years vs 7–10 years) |

| Static Load | Weight on open door | 75 lbs | 160+ lbs | Resistance to abuse (kids hanging) |

| Salt Spray | Hours to Red Rust | 24–48 hours | 96–100+ hours | Rust resistance in humid / coastal areas |

| Operability | Opening Force | < 5 lbs | < 2 lbs | Elderly-friendly, ADA-aligned |

| Permanent Set | Sag after load | Moderate allowed | Minimal allowed | Long-term alignment retention |

Installation—The Final Quality Variable

Even the world’s best Grade 1 hinge will fail if installed poorly. Installation protocol is the final step in ensuring quality.

Cup Hole Specifications

| Specification | Standard Value | Consequence of Error |

|---|---|---|

| Cup Diameter | 35mm | Non-standard size = hinge incompatibility |

| Cup Depth (Standard) | 11–13mm | Too shallow → flange won’t sit flush, screw stress |

| Cup Depth (Soft-Close) | 15.5mm minimum | Too shallow → damper malfunction |

| Depth Too Deep | > 13mm (standard) | Wood too thin → cracking or telegraphing to door face |

The Door Weight/Hinge Count Rules

A common failure in custom cabinetry is overloading the hardware. This is a specification failure, not a hardware failure.

| Door Size | Door Weight | Required Hinges | Consequence of Under-Specification |

|---|---|---|---|

| < 40″ tall | < 15 lbs | 2 hinges | — |

| 40″–60″ tall | < 30 lbs | 3 hinges | Top hinge stretches over time |

| > 60″ tall (Pantries) | < 45 lbs | 4 hinges | Top hinge pulls out of wood |

Warning: Using 2 hinges on a heavy pantry door will cause the top hinge to stretch and eventually pull out of the wood.

Pre-Installation Verification Checklist

Cabinet Preparation:

□ Cabinet boxes square within 1/16″

□ Face frames flat and properly aligned

□ Mounting surfaces clean and dry

□ Correct cabinet depth for hinge type

□ Door overlay type confirmed (inset/partial/full)

Drilling Setup:

□ 35mm Forstner bit sharp and clean

□ Depth stop set correctly (11-13mm standard, 15.5mm soft-close)

□ Drill press square verified

□ Test holes drilled in scrap matching door thickness

□ Painter’s tape applied for tear-out prevention

Hardware Verification:

□ Correct hinge type for overlay specification

□ Mounting plates match hinge model number

□ All screws correct length (10-13mm Euro screws)

□ Soft-close mechanism tested before installation

□ Quantity verified against door count + weight requirements

Tools Ready:

□ Pozidriv #2 driver (NOT Phillips—they strip)

□ Self-centering Vix bit for pilot holes (prevents splitting)

□ Combination square for alignment

□ Pilot hole drill bits (appropriate for wood species)

□ Depth gauge or marked drill bit

Adjustment Protocol for Perfect Alignment

A “quality” door opening experience requires all doors to be perfectly aligned:

Planar Alignment:

• Door face should be flat with cabinet frame

• If top corner sticks out → hinge depth adjustment is off

• Modern 6-way adjustable hinges make correction simple

Soft-Close Tuning:

• On lighter doors, soft-close may be too strong

• Door may hang open instead of closing

• Solution: Deactivate damper on one of two hinges

• This “tuning” is the mark of a master installer

Identifying Counterfeits and Low-Quality Substitutes

The market is rife with “Blum-compatible” or look-alike hardware that mimics the visual appearance of premium brands but lacks the engineering substance.

Visual Spot Checks

| Check Point | Genuine Premium | Counterfeit / Generic |

|---|---|---|

| Branding | “BLUM” stamped into steel cup or arm | Blank, says “KITCHEN,” or random model number |

| Finish Quality | Bright, clean, satin appearance | “Cloudy” or slightly yellow nickel tint |

| Damping Piston | Seamlessly integrated, smooth operation | Bulky, gritty feel, may leak visible oil |

| Steel Thickness | Substantial, heavy | Thin, light |

| Edge Finish | Smooth, deburred | Rough edges, visible tooling marks |

TestGenuine PremiumCounterfeit/GenericThe “Click”Distinct, crisp snap when clipping onto plateMushy feel, excessive force requiredAdjustment ScrewsDoor moves immediately with screw turn2-3 turns before door reacts (backlash)Screw DurabilityHolds under pressureStrips out under normal adjustmentSoft-CloseConsistent, smooth, silentVariable, gritty, or leaks oil

Counterfeit Red Flags Checklist

❌ No manufacturer name stamped on metal

❌ Packaging lacks certifications (BHMA, KCMA)

❌ Price seems “too good to be true”

❌ Inconsistent performance between units

❌ Oil visible around damper seals

❌ Magnetic response on “stainless” claims

❌ No warranty documentation

❌ Seller cannot provide test certifications

Quality Inspection Scorecard

Use this comprehensive scorecard to evaluate hardware samples. Score each category 1-10.

Visual Inspection

| Criteria | Score (1–10) | Notes |

|---|---|---|

| Metal thickness / weight | ___ | 1–3: Thin / flimsy | 8–10: Substantial |

| Edge finish quality | ___ | 1–3: Burrs / rough | 8–10: Smooth |

| Plating consistency | ___ | 1–4: Uneven / spotty | 8–10: Uniform |

| Component precision | ___ | 1–3: Loose fit | 8–10: Tight tolerances |

| Branding / stamping | ___ | 1: None | 10: Clear manufacturer ID |

Functional Testing

| Criteria | Score (1–10) | Notes |

|---|---|---|

| Wiggle test (no play) | ___ | 1–3: Movement / click | 8–10: Solid |

| Snap test (clip-on) | ___ | 1–4: Mushy | 8–10: Crisp, audible click |

| Adjustment response | ___ | 1–3: Backlash | 8–10: Immediate response |

| Soft-close consistency | ___ | 1–5: Varies hinge-to-hinge | 8–10: Identical motion |

| Temperature test (if possible) | ___ | 1–3: Fails cold / hot | 8–10: Stable across range |

CriteriaScore (1-10)NotesCycle test certification___1 = None, 10 = Third-party verifiedBHMA/KCMA certification___1 = None, 10 = Grade 1 certifiedWarranty documentation___2 = 1 year, 10 = LifetimeInstallation instructions___1 = None, 10 = Comprehensive

Total Score Interpretation

| Item | Details |

|---|---|

| Manufacturer / Brand | ________________________ |

| Model / Part Number | ________________________ |

| Supplier / Distributor | ________________________ |

| Installation Date | ________________________ |

| Inspector Name | ________________________ |

| Overall Assessment | ☐ PASS ☐ FAIL ☐ CONDITIONAL |

Frequently Asked Questions (FAQs) for Cabinet Door Opening Mechanisms

Industry Standards & Certification

What is the difference between Grade 1, 2, and 3 certified cabinet hardware under BHMA standards?

ANSI/BHMA A156.9 establishes three distinct performance grades for cabinet hardware:

| Grade | Cycle Life | Static Load | Opening Force | Best Application |

|---|---|---|---|---|

| Grade 1 | 100,000+ cycles | 160+ lbs | < 2 lbs | Commercial, institutional, premium residential |

| Grade 2 | 25,000–50,000 cycles | 75–100 lbs | < 5 lbs | Standard residential |

| Grade 3 | 10,000–25,000 cycles | 50–75 lbs | < 5 lbs | Light-duty residential, budget projects |

Grade 1 represents approximately 27 years of use at 10 cycles per day. Premium manufacturers like Blum exceed Grade 1, testing up to 200,000 cycles. Always specify Grade 1 for projects where long-term performance and reduced callbacks are priorities.

What is the industry-acceptable tolerance for cabinet door sag over a 10-year simulated lifespan?

Under ANSI/BHMA testing, the “permanent set” test measures door sag after static loading. Grade 1 hardware allows minimal permanent deformation—typically less than 1/16″ deviation from original position after the load test. Premium hinges with cold-rolled steel linkage arms (1.0-1.2mm gauge) maintain alignment for decades, while thinner-gauge budget hinges may show measurable sag within 2-3 years of installation. The key quality indicators are steel thickness, pivot pin hardness, and mounting plate rigidity.

Brand Comparisons & Value

Are premium cabinet hinges worth the extra cost for a typical residential kitchen renovation?

Absolutely—here’s the math:

| Factor | Budget Hardware | Premium Hardware |

|---|---|---|

| Cost per kitchen (20 doors) | $60–$90 | $120–$180 |

| Cost difference | — | +$60–$90 |

| Single callback cost | $150–$300 | — |

| Break-even point | — | < 1 callback |

Premium hinges cost approximately $1.50 more per unit, totaling $60-$90 extra for a full kitchen. A single service call to adjust or replace a failing hinge costs $150-$300. The ROI is immediate—premium hardware pays for itself by preventing just one callback while protecting your professional reputation.

How do Blum, Grass, and Salice soft-close hinges compare in performance?

All three are premium European manufacturers, but each has distinct characteristics:

| Brand | Cycle Rating | Soft-Close Tech | Key Strength | Price |

|---|---|---|---|---|

| Blum | 200,000 | BLUMOTION | Widest adjustment, 59-part precision | $$$ |

| Grass | 100,000+ | Tiomos 4D | Lowest pull force | $$–$$$ |

| Salice | 80,000+ | Smove | European design compatibility | $$ |

All three significantly outperform generic alternatives. Selection often depends on specific project requirements: Blum for maximum adjustment flexibility, Grass for ergonomic ease, Salice for European-style cabinetry compatibility.

Technical Performance

How do temperature variations affect the viscosity and performance of hydraulic soft-close fluids?

Temperature significantly impacts soft-close damper performance:

| Temperature | Budget Damper | Premium Damper |

|---|---|---|

| Cold (50–60°F) | Stiff / won’t close | Normal |

| Optimal (65–85°F) | Acceptable | Normal |

| Hot (85–95°F) | Loose / slams | Normal |

Premium manufacturers like Blum use engineered silicone fluids that maintain consistent viscosity across temperature extremes. This is critical for kitchens with variable temperatures (near ovens, in unconditioned spaces, etc.). Budget dampers using mineral oils become problematic in garages, basements, or seasonal homes.

What are the visual signs of a cheap or failing cabinet hinge that I can look for?

Signs of Poor Quality (New Hardware): • Thin, lightweight construction (compare weight to known premium brand) • Cloudy or yellowish tint to nickel plating (vs. bright, satin finish) • No manufacturer name stamped on metal • Rough edges or visible tooling marks • Mushy feel when clipping onto mounting plate • Adjustment screws with excessive backlash (2-3 turns before door moves)

Signs of Failing Hardware (Installed): • Door sag visible at reveal lines • “Click” or play when lifting door handle (wiggle test failure) • Oil leaking around soft-close damper • Inconsistent soft-close engagement point • Doors that slam despite soft-close mechanism • Rust or corrosion on metal surfaces

What materials perform best in salt spray tests for cabinet hardware (e.g., 316 vs 304 stainless steel)?

For corrosion resistance in marine, coastal, or high-humidity environments:

| Material | Salt Spray | Magnetic | Recommended Use |

|---|---|---|---|

| 316 Stainless | 1000+ hrs | No | Marine / coastal |

| 304 Stainless | 96–200 hrs | Weak | Outdoor kitchens |

| 201 Stainless | 48–72 hrs | Yes | Indoor ONLY |

| Nickel-Plated | 24–48 hrs | Yes | Dry interiors |

The Magnet Test: Carry a neodymium magnet on site. If it sticks firmly to “stainless” hardware, it’s likely 201-series or lower grade and will rust in humid conditions.

Lift Systems & Specialty Mechanisms

What are the common points of failure in pneumatic gas struts used in cabinet lifts?

Gas struts (pneumatic) have inherent limitations compared to mechanical spring systems:

| Material | Salt Spray | Magnetic | Recommended Use |

|---|---|---|---|

| 316 Stainless Steel | 1000+ hours | No | Marine, yacht, direct coastal exposure |

| 304 Stainless Steel | 96–200 hours | Weak | Outdoor kitchens, humid bathrooms |

| 201 Stainless Steel | 48–72 hours | Yes | Indoor ONLY — avoid humidity |

| Nickel-Plated Steel | 24–48 hours | Yes | Dry, climate-controlled interiors only |

Recommendation: For builders offering warranties, mechanical spring packs (like Blum AVENTOS) are the only responsible choice—they don’t leak, maintain performance across temperature extremes, and last decades without replacement.

What hinge type is recommended for heavy, oversized doors in institutional settings?

For high-cycle commercial environments (hospitals, schools, restaurants):

| Door Specification | Recommended Solution | Key Requirements |

|---|---|---|

| > 60″ tall, < 45 lbs | 4+ hinges, BHMA Grade 1 | 100,000+ cycles, 160 lb static load |

| > 30″ wide | Heavy-duty concealed hinges | Reinforced mounting plates, wider arm geometry |

| High-frequency use | Commercial-grade soft-close | Adaptive damping, temperature-stable fluid |

| ADA compliance | Low-force hinges | < 2 lbs opening force (BHMA Grade 1) |

Specify Blum or Grass commercial lines with documented cycle testing. Avoid budget hardware entirely—the callback and replacement costs in commercial settings are prohibitive.

Push-to-Open Systems

What are the most common complaints or failure modes for handle-less push-to-open systems?

Push-to-open mechanisms have the highest variance in quality between manufacturers:

| Failure Mode | Cause | Budget Hardware | Premium Hardware (TIP-ON) |

|---|---|---|---|

| “Bounce” problem | Latch fails to catch | Common (1–2 years) | Rare — soft-close integration |

| Spring weakening | Metal fatigue | 1–3 years | 10+ years |

| Accidental opening | Trigger too sensitive | Common complaint | Calibrated touch sensitivity |

| Won’t stay closed | Latch wear | 2–4 years | 10+ years |

| Vibration triggering | No lockout feature | Opens during vibration / earthquakes | 2 mm negative travel required |

Premium Solution: Blum TIP-ON BLUMOTION combines push-to-open with soft-close damping—the door opens on push, but when closed, the soft-close catches it, slows it down, and the latch engages silently. This eliminates the bounce problem entirely.

Accessibility & Special Applications

What is the maximum opening force allowed for cabinet doors under ADA guidelines?

For ADA compliance and accessibility:

| Standard | Maximum Opening Force | Application |

|---|---|---|

| ADA (Americans with Disabilities Act) | ≤ 5 lbs (22.2 N) | General accessibility compliance |

| BHMA Grade 1 | < 2 lbs (8.9 N) | Premium standard — exceeds ADA requirements |

| BHMA Grade 2–3 | < 5 lbs (22.2 N) | Meets minimum ADA threshold |

For healthcare facilities, assisted living, and ADA-compliant residential projects, always specify Grade 1 hardware with documented opening force specifications. Soft-close mechanisms should include deactivation features to reduce resistance on lightweight doors.

Safety & Child Protection

Do aftermarket child safety locks void the warranty on high-end soft-close cabinet hinges?

Generally, aftermarket safety devices do not void hinge warranties if: • Installation doesn’t require modification to the hinge mechanism • The device doesn’t interfere with the soft-close damping action • No drilling or permanent alteration to hinge components

However, some potential issues to consider:

| Concern | Risk | Mitigation |

|---|---|---|

| Increased closing force | May accelerate damper wear | Choose magnetic latches over mechanical devices |

| Door alignment stress | Repeated catching may strain hinges | Perform proper hinge adjustment after installation |

| Integrated solutions | Best long-term approach | Specify cabinets with built-in child locks |

Recommendation: When child safety is a priority, specify cabinetry with integrated safety features rather than retrofitting aftermarket devices.

Real Estate & Property Value

Do home inspectors specifically check for the brand and function of cabinet hardware during a sale?

Home inspectors typically check: • Door alignment and operation (open/close smoothly) • Evidence of sagging or misalignment • Soft-close function (if advertised) • Signs of wear, damage, or rust

While inspectors rarely document specific hardware brands, real estate agents increasingly cite “soft-close cabinetry” as a selling point in listing descriptions. Quality hardware impacts:

| Increased closing force | May accelerate damper wear | Choose magnetic latches over mechanical devices |

| Door alignment stress | Repeated catching may strain hinges | Proper hinge adjustment after installation |

| Integrated solutions | Best long-term approach | Specify cabinets with built-in child locks |

For builders and flippers, premium hardware is a cost-effective strategy to elevate perceived home value—the $60-90 kitchen upgrade can influence buyers’ overall impression of construction quality.

Commercial & Manufacturing

What is the ROI on specifying premium hardware in terms of reduced customer complaints and service calls?

The business case for premium hardware is compelling:

| Metric | Budget Hardware | Premium Hardware | Difference |

|---|---|---|---|

| Hardware cost (20-door kitchen) | $60–$90 | $120–$180 | +$60–$90 |

| Callback rate | 1–3% | < 0.5% | −0.5–2.5% |

| Cost per callback | $150–$300 | $150–$300 | — |

| Expected callbacks per 100 kitchens | 1–3 | < 0.5 | −0.5–2.5 |

| Callback cost per 100 kitchens | $150–$900 | < $150 | −$0–$750 |

| Hardware upgrade cost (100 kitchens) | — | $6,000–$9,000 | — |

| Net savings per 100 kitchens | — | −$5,250 to +$750 | Break-even to positive |

Additional ROI Factors: • Reputation protection (negative reviews cost future business) • Warranty claim reduction • Installation efficiency (premium hardware has better tolerances) • Client referrals from satisfied customers

For high-volume contractors, the math strongly favors premium hardware once reputation and opportunity costs are factored in.

How does screw pull-out strength differ between particle board and solid wood for hinge mounting?

Substrate material significantly impacts hardware longevity:

| Material | Screw Pull-Out Strength | Humidity Sensitivity | Recommended Hardware |

|---|---|---|---|

| Solid Hardwood (Maple, Oak) | Highest (800+ lbs) | Low | Any grade; pilot holes recommended |

| Plywood (Cabinet Grade) | High (400–600 lbs) | Low–Moderate | Grade 1–2; standard mounting |

| MDF (Medium Density Fiberboard) | Moderate (200–400 lbs) | Moderate | Grade 1 with reinforced plates |

| Particle Board | Lowest (100–250 lbs) | High | Premium only; avoid overtightening |

Critical Installation Notes: • Particle board fails most often from overtightened screws—the material compresses and loses grip • MDF requires pilot holes to prevent splitting • In humid environments, particle board swells and loses screw retention • For heavy doors on particle board, specify reinforced mounting plates or dowel inserts

Conclusion: The Business Case for Premium Hardware

For dealers, contractors, and builders, the “opening mechanism” is not merely a pivot point; it is a pivotal point of value. It is the tactical interface where the homeowner physically connects with the quality of their investment every single day.

Key Takeaways for Procurement

| Step | Action | Verification Method |

|---|---|---|

| 1. Check the Grade | Is it ANSI / BHMA Grade 1? | Look for 100,000+ cycle documentation |

| 2. Check the Brand | Is the logo stamped on the steel? | Visual inspection — avoid unbranded generics |

| 3. Check the Weight | Calculate door weight | Verify hinge count / lift power factor |

| 4. Check the Environment | Assess moisture exposure | Use 304 stainless for outdoor / coastal |

| 5. Test the Feel | Perform field tests | Wiggle, snap, adjustment response |

| 6. Verify Documentation | Request certifications | BHMA, KCMA, salt spray results |

The ROI Summary

| Investment | Cost | Protection Value |

|---|---|---|

| Premium hardware upgrade | $60-90 per kitchen | Avoids $1,000+ in potential callbacks |

| Quality verification time | 15 minutes per shipment | Prevents installation of defective units |

| Proper installation protocol | Standard labor | Eliminates specification-related failures |

The ROI Summary

| Investment | Cost | Protection / Value |

|---|---|---|

| Premium hardware upgrade | $60–$90 per kitchen | Prevents $1,000+ in callbacks & repairs |

| Quality verification time | ~15 minutes per shipment | Stops defective or counterfeit hardware before install |

| Improper specification | Hidden long-term cost | Leads to sagging doors, warranty claims, negative reviews |

| Net Result | Minimal upfront spend | Break-even to strongly positive ROI |

By mastering these metrics, you transform hardware from a commodity line item into a competitive advantage.

Partner with USA Cabinet Express for Premium Cabinet Solutions

At USA Cabinet Express, we understand that quality hardware is the foundation of lasting cabinet performance. Our expert team works exclusively with contractors, dealers, and builders to specify premium cabinet solutions that minimize callbacks and maximize client satisfaction.

Our Hardware Standards: • Fabuwood cabinetry with Blum Compact BLUMOTION hinges standard

• Wolf cabinetry with premium soft-close mechanisms

• Full line of AVENTOS lift systems available

• All hardware meets or exceeds BHMA Grade 1 specifications

Visit Our Professional Showrooms

Austin, Texas

📍 2112 Rutland Dr #185, Austin, TX 78758

📞 Call: (469) 336-9201

📧 Email: markg@usacabinetexpress.com

🕐 Hours: Mon-Fri 8AM-6PM, Sat 9AM-5PM, Sun Closed

Chesapeake, Virginia ⚠️ Appointment Only

📍 1543 Sams Cir, Chesapeake, VA 23320

📞 Call: (757) 296-6669 | (757) 937-1737

📧 Email: chesapeake@usacabinetexpress.com

🕐 Hours: Mon-Fri 8AM-6PM, Sat 9AM-5PM, Sun Closed

📍 Serving: Chesapeake, Virginia Beach, Norfolk, Portsmouth, Hampton Roads

St. Louis, Missouri

📍 2605 S Hanley Rd, Saint Louis, MO 63144

📞 Call: (314) 900-0440

📧 Email: stlouis@usacabinetexpress.com

🕐 Hours: Mon-Sat 8AM-6PM, Sun Closed

📍 Serving: St. Louis, Brentwood, Webster Groves, Greater St. Louis area

Additional Locations:

Dallas, Texas – (469) 990-2200

Houston, Texas – (281) 306-6060

Fredericksburg, Virginia – (540) 515-1500

🌐 Explore online at usacabinetexpress.com

Schedule a Professional Consultation:

Contact your nearest showroom to discuss your project requirements, review hardware samples, and receive expert guidance on specification and installation best practices.

Start your kitchen transformation today with USA Cabinet Express—where quality, precision hardware, and professional support come together to build your reputation, one installation at a time.

Related Professional Resources

Last updated: December 2025 | For professional contractors, dealers, and builders